On the morning of June 17, 2025, China’s first domestically developed high-power, large-area magnetron sputtering equipment—with fully independent intellectual property rights—officially passed acceptance testing at the Jinjia Industrial Park in Bao’an District, Shenzhen. The equipment was jointly developed by Peking University Shenzhen Graduate School, Jinjia Group, and the Houlang Laboratory in Shenzhen. Its successful acceptance marks a major breakthrough in China’s core equipment for next-generation energy batteries, and represents a milestone achievement in industry-academia-research collaboration under the framework of Peking University’s “New Engineering” initiative.

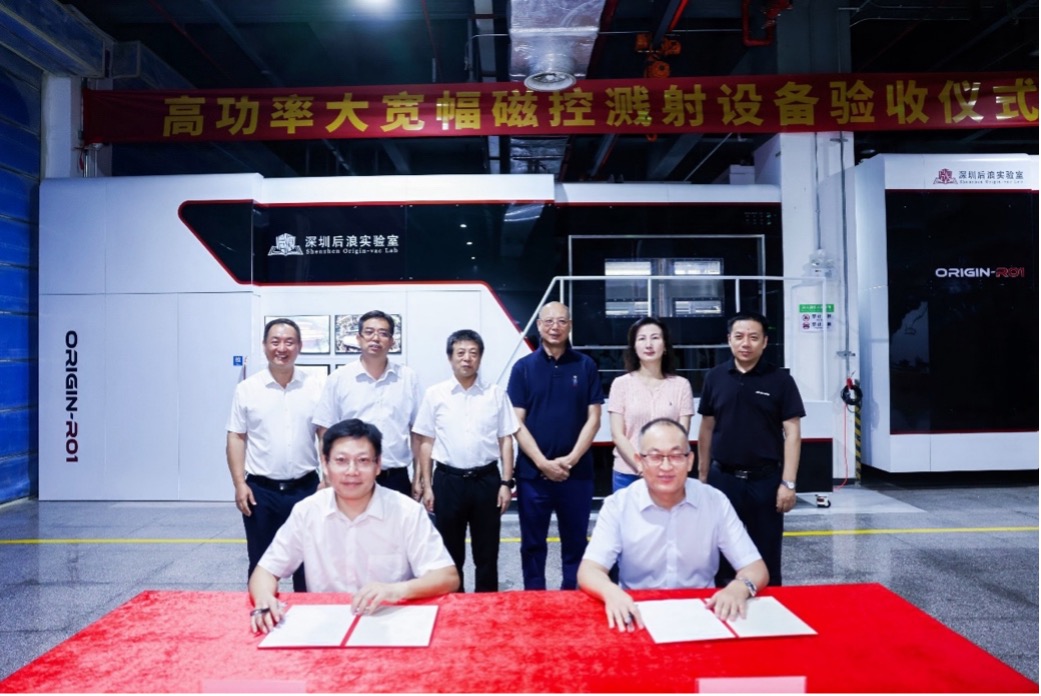

Signing Ceremony at the Acceptance Site

The acceptance ceremony was hosted by Wanli Luo, Executive Vice General Manager of Jinjia Juneng. Attendees included Prof. Wenchang Tan, Party Secretary of Peking University Shenzhen Graduate School; Prof. Hongwei Niu, Vice Dean of the Graduate School; and Prof. Ruqiang Zou, Dean of both the School of Materials Science and Engineering and the School of Advanced Materials at Peking University. On behalf of Jinjia Group, the ceremony was attended by Luoyu Qiao, Chairman; Xiaohua Li, Vice President and Board Secretary; Wei Lü, Vice President and Chief Engineer; and Qinfang Yu, General Manager of Jinjia Juneng, along with the entire project team. Together, they witnessed the successful delivery of this major technological achievement.

Equipment Acceptance and Launch Ceremony

This achievement was supported by a major technological innovation project of the Shenzhen Municipal Government and marks the first successful application of high-power continuous magnetron sputtering technology independently developed by Prof. Zhongzhen Wu’s team at the School of Advanced Materials, Peking University. The project achieved a breakthrough in addressing the efficiency and quality bottlenecks in the production of composite current collectors for new energy batteries. As the first industrial-scale system capable of simultaneous front-and-back coating (thickness > 1 μm) via a one-step magnetron sputtering process, this equipment offers a simplified production flow, high throughput, and performance metrics that fully meet design standards—demonstrating strong market competitiveness.

Full View of the Equipment

The equipment features several key technological innovations:

1. Fully protected by a complete set of patents, with independent intellectual property rights;

2. Suitable for continuous production using PP and PET composite substrates;

3. Copper foil winding speed increased tenfold, compatible with both one-step and two-step processes;

4. Concurrent coating and maintenance, with fast component replacement—one production cycle lasts 20 hours, and reel changeover takes only 2 hours;

5. Width range of 0.6 to 2.0 meters, with excellent uniformity and thickness variation within 10%;

6. Strong film adhesion without the need for an intermediate layer;

7. Novel structural design allows for alternating front-and-back coating, effectively relieving film stress;

8. Deposited copper layers are dense, oxidation-resistant, and offer high conductivity.

Following the ceremony, representatives from all collaborating parties held a discussion on the R&D process and the industrialization potential of the equipment. Peking University Shenzhen Graduate School expressed its commitment to deepening its strategic cooperation with Jinjia Group, jointly developing high-value-added core materials, and building a leading innovation hub in thin-film deposition technologies.

The successful development of this equipment provides critical technical support for China's independent and controllable new energy battery materials supply chain. The R&D team welcomes inquiries from companies in the composite current collector sector to explore collaboration and promote the transformation of this technological achievement.