Silicon monoxide (SiOx, 0<x<2), with its high specific capacity, low operating potential, and low cost, is regarded as an ideal anode material for achieving high-energy-density lithium-ion batteries. Previous research by the team of Feng Pan and Luyi Yang from the School of Advanced Materials (SAM) revealed that the severe expansion–contraction of SiOx during cycling leads to continuous thickening of the solid electrolyte interphase (SEI), ultimately disrupting the electron percolation network (Nat. Commun., 2023, 14, 6048). From the perspective of interfacial stability design, constructing an SEI with a LiF-rich inner layer has been demonstrated to significantly enhance stability (Angew. Chem. 2025, 64, e202413927). Achieving such a structure requires the preferential formation of LiF at relatively high potentials. The commonly used low-cost electrolyte additive fluoroethylene carbonate (FEC) can decompose within the voltage range of 1.0–1.4 V (vs. Li+/Li) to form a LiF-rich SEI. However, the FEC reduction process has a high energy barrier, leading to incomplete decomposition during the initial cycling stages. As a result, the amount of LiF formed is limited and its distribution is disordered. This inhomogeneous SEI structure disrupts lithium-ion transport and induces interfacial stress concentration, severely impairing the cycling stability of the battery.

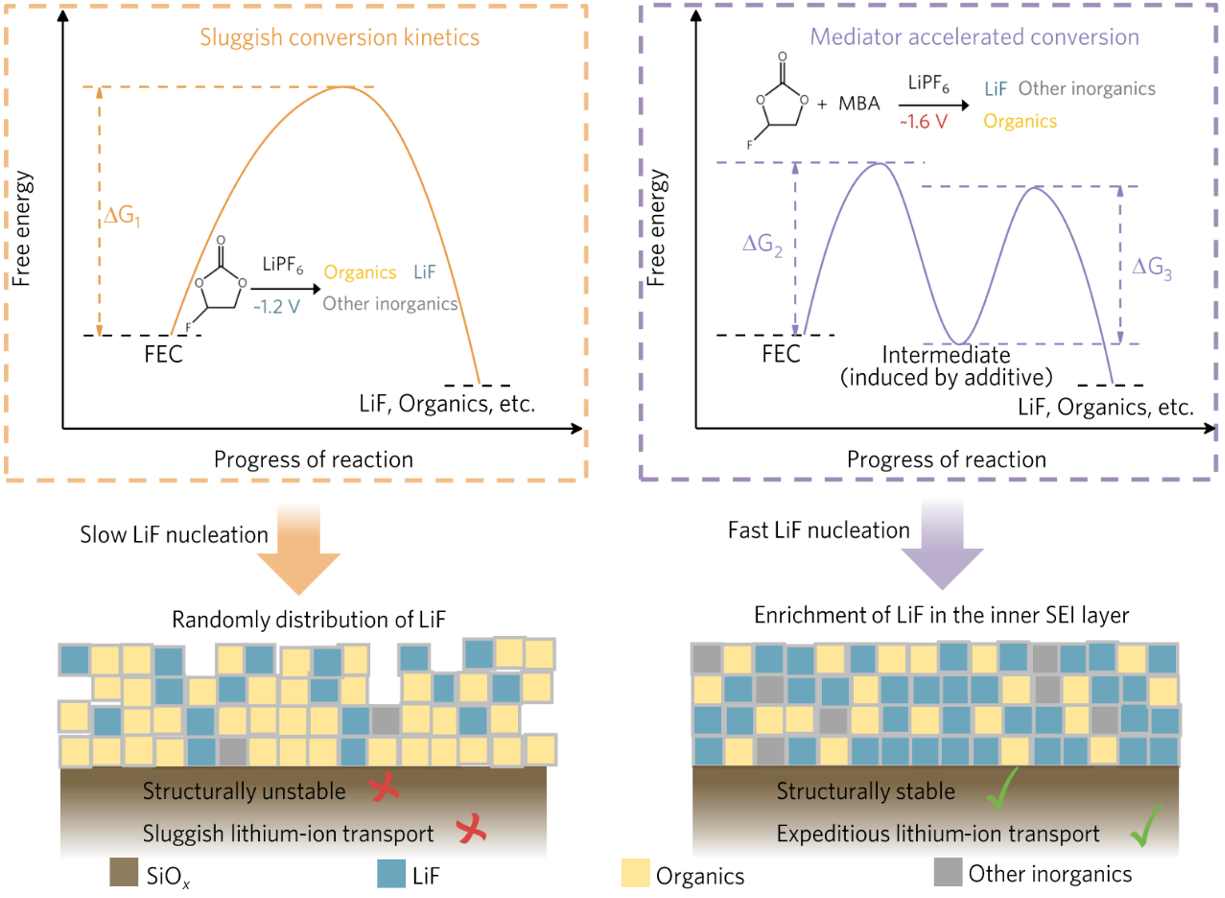

Figure 1. Design Concept and Mechanism of MBA-induced Rapid LiF Nucleation: Constructing a LiF-rich inner SEI Layer

Inspired by microbial degradation of complex organic compounds, the research team has innovatively developed an electrolyte co-additive system based on bis(2-methoxyethyl)amine (MBA). This system effectively regulates the transformation of the commonly used electrolyte additive FEC into the target SEI product LiF, thereby enabling the formation of an ideal SEI structure on the surface of SiOx anodes. Specifically, MBA attacks the carbonyl carbon of FEC to generate an intermediate, FMLi, which exhibits enhanced thermodynamic and kinetic favorability for electrochemical reduction. This accelerates the preferential nucleation of LiF. As a result, a gradient-structured SEI is formed on the SiOx anode, with a LiF-rich inner layer that offers both high mechanical strength and excellent lithium-ion conductivity. This stable SEI effectively accommodates the volumetric changes of silicon-based anodes, significantly improving the cycling retention and rate capability of SiOx||Li half cells. The stable cycling performance of pouch full cells further demonstrates the practical value of this strategy. The proposed intermediate-regulation approach not only enhances the utilization efficiency of conventional additives but also provides a new perspective for molecular design of electrolyte systems and the development of next-generation high-performance lithium-ion batteries. The study, titled “Mediating Solid Electrolyte Interphase Formation Kinetics on SiOx Anodes Using Proton Acceptors” (DOI: 10.1002/anie.202505832), was recently published in Angewandte Chemie International Edition.

This work was jointly supervised by Professor Feng Pan and Associate Researcher Luyi Yang at Peking University. Haoliang Wang, a master's student, and Hao Zhang, a master's graduate (now a Ph.D. student at City University of Hong Kong), are co-first authors. The research was supported by the National Natural Science Foundation of China, the International Joint Research Center for Power Battery and Materials for Electric Vehicles, the Guangdong Provincial Key Laboratory of New Energy Materials Design and Computation, and the Shenzhen Key Laboratory of Materials Genome for New Energy Materials Fabrication and Characterization.