Perovskite solar cells have attracted widespread attention due to their excellent photovoltaic conversion efficiency and low-cost manufacturing potential. However, insufficient long-term stability and performance degradation in large-area modules remain critical bottlenecks hindering their large-scale industrialization. Compared to traditional metal electrodes, carbon electrodes offer advantages such as low cost, high stability, and hydrophobicity, which help enhance overall device durability. Moreover, carbon electrodes are more compatible with printing processes, making them an ideal choice for achieving fully printed perovskite modules. Despite this promise, the photovoltaic conversion efficiency of carbon-based modules has long lagged significantly behind that of metal-electrode devices, posing a pressing challenge in the field.

Recently, a collaborative team led by Professor Shihe Yang (School of Advanced Materials, Peking University Shenzhen Graduate School; also Senior Researcher at Shenzhen Bay Laboratory), together with researchers from Beihang University and Beijing Institute of Technology, proposed a scalable vapor-phase post-treatment strategy. This approach enables uniform passivation of large-area perovskite films, dramatically improving the photovoltaic conversion efficiency and long-term stability of fully printed carbon-based modules. The findings were published in the prestigious journal Nature Photonics under the title “Vapour-assisted surface treatment for highly stable fully printed carbon-electrode perovskite solar modules”.

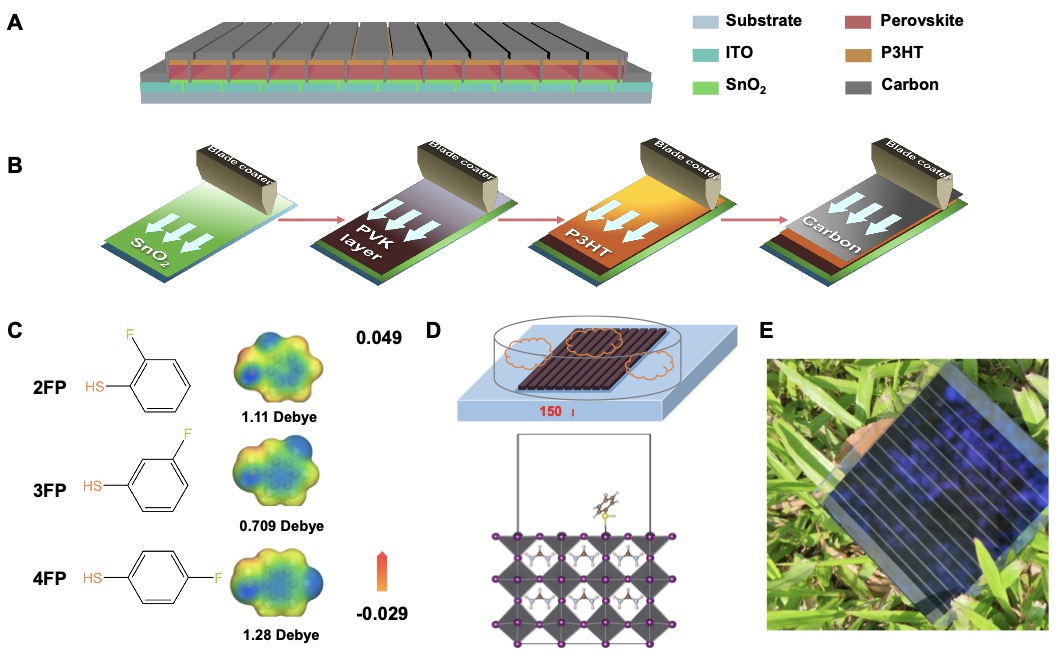

Figure 1. (A) Device structure, (B) fabrication process, (C) molecular structure and charge distribution of FP molecules, (D) vapor treatment setup and interaction mechanism, and (E) outdoor demonstration photo of the fully printed carbon-based perovskite solar module.

The vapor-phase post-treatment strategy utilizes a carefully selected series of low-boiling-point liquid fluorobenzenethiol molecules (2FP, 3FP, 4FP). Through mild thermal evaporation, uniform passivation of large-area perovskite films is achieved. Experimental and theoretical calculations reveal that the thiol group (–SH) in fluorobenzenethiol molecules effectively binds with undercoordinated Pb²⁺ ions on the perovskite surface, efficiently passivating interface defects. The study further demonstrates that vapor treatment enables saturated molecular adsorption, achieving efficient passivation while avoiding the formation of excessively thick insulating layers. Additionally, molecular configuration plays a critical role in adsorption kinetics during vapor treatment, with the structurally symmetric 4FP molecule exhibiting the strongest interaction with undercoordinated Pb²⁺ ions and the highest adsorption capacity. Overall, this vapor-phase post-treatment strategy effectively reduces surface defect density in large-area perovskite films, suppresses non-radiative recombination, and accelerates charge extraction—significantly enhancing module photovoltaic performance.

Leveraging this strategy, the team successfully fabricated fully printed carbon-electrode perovskite solar modules with an active area of 50 cm², achieving a photovoltaic conversion efficiency of 20.41%, with a third-party certified efficiency of 19.26%—the highest reported to date for carbon-based perovskite modules.

In terms of stability, unpackaged modules retained nearly full efficiency after 1020 hours of continuous operation at 65°C under 1-sun illumination. Under harsh damp-heat conditions (85°C, 85% relative humidity), the modules maintained over 84% of initial efficiency after 2280 hours, demonstrating outstanding resistance to high temperature and humidity.

This study, through an ingenious vapor-phase post-treatment strategy, successfully overcomes the long-standing trade-off between low-cost, scalable fabrication and high performance in carbon-based perovskite modules, providing a viable technical pathway for transitioning perovskite solar modules from laboratory to industrial application.

Professor Shihe Yang (School of Advanced Materials, Peking University; Senior Researcher, Shenzhen Bay Laboratory), Professor Haining Chen (Beihang University), and Associate Professor Yang Bai (Beijing Institute of Technology) are the co-corresponding authors. PhD students Xiaozhen Wei and Kai Zhang from the School of Advanced Materials are co-first authors. The research was supported by the National Natural Science Foundation of China, the Shenzhen Peacock Plan, the Nanshan Pilot Team Program, and other initiatives.

Link to the paper: https://doi.org/10.1038/s41566-025-01790-2