In impact protection applications such as ballistic armor, vehicle shielding, and aerospace, the dynamic strength and dynamic toughness of fiber materials are critical performance indicators determining protective efficacy. However, widely used polymeric fibers still face significant challenges: on one hand, low polymer chain orientation, high porosity, and weak interfacial interactions within fibers lead to easy chain slippage under external impact, preventing full utilization of the material’s intrinsic strength and toughness. Currently, the dynamic strength of polymer fibers is generally below 8 GPa, and dynamic toughness is less than 300 MJ·m⁻³, far from ideal application levels. On the other hand, the classic strength-toughness trade-off in materials science makes it extremely difficult to simultaneously enhance both properties. These factors severely limit the further development and application of polymer fibers in impact protection.

Recently, Academician Jin Zhang’s team from the School of Advanced Materials at Peking University Shenzhen Graduate School, in collaboration with Researcher Xianqian Wu’s team from the Institute of Mechanics, Chinese Academy of Sciences, and Professor Enlai Gao’s team from Wuhan University, proposed an innovative strategy of “regulating carbon nanotube orientation distribution + optimizing fiber hierarchical structure.” By synergistically combining molecular chain design and multi-stage drawing techniques, the team introduced a small amount of modified long carbon nanotubes into a novel heterocyclic aramid system, successfully achieving a substantial simultaneous improvement in dynamic strength and dynamic toughness of carbon nanotube/heterocyclic aramid composite fibers.

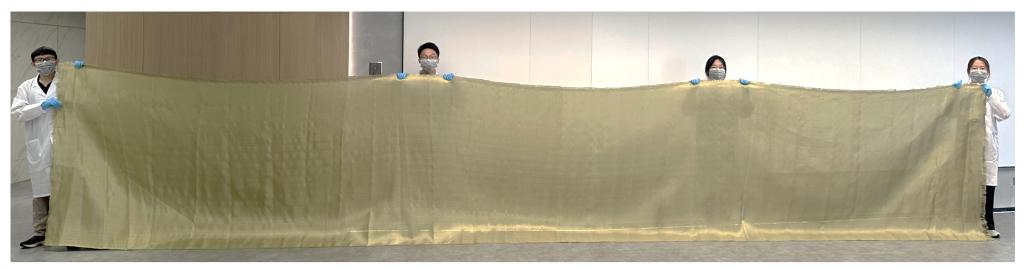

The team first modified long carbon nanotubes and incorporated ether-containing monomers into the traditional heterocyclic aramid system. Subsequently, a multi-stage drawing process was designed and implemented. The introduction of ether-containing monomers significantly increased the draw ratio in the coagulation bath, promoting high-orientation alignment of both carbon nanotubes and heterocyclic aramid molecular chains, thereby optimizing the fiber’s hierarchical structure. This optimization enhanced interfacial interactions, improved load transfer efficiency, and under high-speed impact, suppressed molecular chain slippage while promoting chain fracture—fully exploiting material performance. Experimental results showed that under a high strain rate of 1600 s⁻¹, the prepared carbon nanotube/heterocyclic aramid composite fibers achieved a dynamic strength of up to 10 GPa and a dynamic toughness of 700 MJ·m⁻³. Furthermore, fabrics woven from scaled-up production of these composite fibers also exhibited excellent impact protection performance, laying a solid foundation for large-scale applications.

The research findings, titled “Aramid fibers with dynamic strength up to 10 GPa and dynamic toughness up to 700 MJ m⁻³,” were published in the internationally renowned journal Matter. The achievement has been reported by multiple domestic and international media outlets, including Newsweek and New Scientist, and was featured as a headline story in New Scientist, reflecting widespread attention from the global academic community.

Figure 1. Publication page of this study in the journal Matter

Figure 2. This research achievement featured as a headline in New Scientist

Figure 3. Schematic of the preparation, mechanical properties, and reinforcement mechanism of carbon nanotube/heterocyclic aramid composite fibers

Figure 4. Fabric woven from carbon nanotube/heterocyclic aramid composite fibers

Academician Jin Zhang (Peking University), Researcher Zhenfei Gao (Beijing Graphene Research Institute), Senior Engineer Kun Jiao (Peking University), Researcher Xianqian Wu (Institute of Mechanics, Chinese Academy of Sciences), and Professor Enlai Gao (Wuhan University) are the co-corresponding authors. Dr. Jiajun Luo (Peking University), Dr. Xudong Lei (Institute of Mechanics, Chinese Academy of Sciences), PhD candidate Xiangzheng Jia (Wuhan University), and PhD candidate Mengdie Li (Peking University) are the co-first authors. The research was supported by the National Natural Science Foundation of China, the Shenzhen Peacock Plan, and other programs.

Link to the paper: https://doi.org/10.1016/j.matt.2025.102496