Against the backdrop of global energy transition, lithium-ion batteries, as the core electrochemical energy storage technology, are facing severe challenges: the energy density of commercialized batteries is approaching its theoretical limit, while next-generation battery systems suffer from critical safety and cycle-life issues. These challenges stem from the inherently complex nature of battery R&D characterized by “cross-scale, long-cycle, and multi-factor” features: spatially spanning from atomic/nano-scale microscopic reactions to meter-scale cell/pack macroscopic performance; temporally ranging from nanosecond-level ion migration and chemical reactions to hour-level charge-discharge processes; the full R&D chain from material discovery to cell manufacturing and scale-up relies heavily on time-consuming trial-and-error experiments; multiple coupled physico-chemical fields make failure mechanisms extremely difficult to decipher.

To address these challenges, the research group led by Associate Prof. Jiaxin Zheng from the School of Advanced Materials (SAM) at Peking University, in collaboration with Shenzhen Eacomp and Contemporary Amperex Technology Co., Limited (CATL), systematically proposed and elaborated a transformative AI-driven R&D paradigm — Battery Design Automation (BDA). By integrating multi-scale simulation technologies with state-of-the-art artificial intelligence algorithms into a unified platform, BDA achieves full-chain coverage from micro-scale material screening to macro-scale battery system performance prediction, fundamentally shifting battery R&D from traditional “empirical trial-and-error” to “simulation-driven design automation”. The related achievements have been published as a review article entitled “AI-Driven Next-generation Lithium-Ion Battery Design Automation (BDA) Software” in National Science Open (NSO), a comprehensive English-language academic journal supervised by the Chinese Academy of Sciences and published by Science Press.

Link to the paper: https://www.sciengine.com/NSO/doi/10.1360/nso/20250062

Liu Zekai, Lai Genming, Zuo Yunxing, et al. AI-Driven Next-generation Lithium-Ion Battery Design Automation (BDA) Software [J/OL]. National Science Open, 2025, 2025-11-04. DOI: 10.1360/nso/20250062

Figure 1. Screenshot of the Paper

The review is structured in four chapters: Chapter 1 elucidates the pivotal role of batteries in the global energy landscape and the fundamental bottlenecks in their R&D, justifying the necessity of BDA as a paradigm shift from experience-dependent trial-and-error to simulation-driven design automation; Chapter 2 delves into the scientific foundation of BDA, systematically reviewing AI-enabled multi-scale simulation technologies that accurately and efficiently evaluate battery performance from microscopic mechanisms to macroscopic behavior; Chapter 3 details the industrial implementation of BDA, including software architecture, platform ecosystem, and representative engineering application cases, demonstrating its capability to solve real-world R&D challenges; Chapter 4 summarizes the core insights, analyzes remaining challenges, and outlines future development directions and feasible implementation paths for BDA.

1. Background and Concept of BDA

Lithium-ion batteries face dual challenges: commercialized cells are approaching their energy-density ceiling, while next-generation systems suffer from severe safety and longevity issues. These difficulties arise from three intrinsic characteristics of battery R&D: (1) Cross-scale: spanning >9 orders of magnitude in both space (nanometer atomic arrangement to meter-scale packs) and time (nanosecond reactions to hour-level cycling); (2) Long-cycle: the entire chain from material design → cell prototyping → scale-up manufacturing requires extensive trial-and-error, often lasting months to years; (3) Multi-factor: tightly coupled multi-physics fields make failure analysis extremely complex.

Drawing inspiration from the success of Electronic Design Automation (EDA) in the semiconductor industry and recent breakthroughs of AI for Science (AI4S) in battery research, the team innovatively proposed the BDA paradigm. BDA establishes a unified platform that deeply integrates multi-scale simulation with cutting-edge AI algorithms, enabling AI-driven simulation across atomic-to-system levels, thereby achieving a fundamental shift from “trial-and-error” to “automated design” and dramatically accelerating next-generation battery development.

Figure 2. Schematic Diagram of the Application of the BDA Architecture in Multiscale Modeling and Simulation

2. Core Technologies of BDA

The BDA technical framework revolves around three pillar technologies:

(1) Cross-scale Parameter Transfer and Intelligent Coupling

High-fidelity multi-scale simulation hinges on lossless transfer of parameters from lower to higher scales. Machine-learning force fields (MLFF) can reveal lithium deposition behavior on different Cu facets, intrinsic self-healing of dendrites, and microscopic mechanisms of external pressure suppressing dendrites, while providing critical interfacial kinetic parameters for meso-scale phase-field models. High-throughput computation combined with AI screening rapidly discovers new cathode and solid-electrolyte materials, whose intrinsic properties (e.g., ionic conductivity) directly define material parameters in macro-scale continuum models. Coarse-grained molecular dynamics (CGMD) coupled with Bayesian optimization efficiently extracts meso-scale transport properties of complex polymer electrolytes to feed macro-scale performance evaluation.

(2) AI-Enhanced High-Efficiency Simulation

Traditional simulation faces an inevitable trade-off between accuracy and computational cost. BDA resolves this dilemma by embedding physical laws into AI models. Physics-Informed Neural Networks (PINN) embed governing equations into the loss function, achieving accurate and efficient solutions for complex multi-physics problems such as the Pseudo-2D (P2D) model and battery SOH prediction. Further developed Physics-Informed Composite Networks (PICN) improve convergence and multi-objective performance. AI surrogate models can replace expensive physics simulations, reducing design cycles from weeks to hours. AI-based 3D microstructure reconstruction from real electrodes significantly enhances the fidelity of macro-scale predictions.

(3) Generative AI and Inverse Design

The ultimate goal of BDA is performance-oriented inverse design of batteries. Generative AI models learn complex mappings between material/structure parameters and performance, then proactively generate candidate solutions that meet specific targets (e.g., ultra-high ionic conductivity, superior stability, and fast-charging capability). Platforms such as Uni-Electrolyte use generative AI to design novel electrolyte molecules and predict synthetic routes. ML-assisted CGMD enables inverse design of high-conductivity polymer electrolytes. The closed loop of “target performance → material/structure generation → simulation validation” dramatically accelerates discovery of next-generation battery components.

Figure 3. Cross-scale Parameter Transfer and Intelligent Coupling

3. Industrial Implementation and Ecosystem of BDA

The development of BDA software platforms is inseparable from real industrial scenarios. The team introduced the first domestically developed full-stack BDA platform consisting of three core software products: Matter Craft®, BatTwin Craft® and BatMind Craft®.

Figure 4. Matter Craft®, BatTwin Craft®, BatMind Craft®

(1) Matter Craft®: Focuses on micro-scale material design. Integrates first-principles and molecular dynamics tools (Hylanemos, CP2K, PySCF, LAMMPS, MLFF, etc.) to design and optimize cathode/anode materials, liquid/solid electrolytes, and separators. Its in-house plane-wave DFT code Hylanemos provides more accurate cathode calculations through precise initial magnetic moment prediction.

(2) BatTwin Craft®: Builds a multi-scale simulation framework bridging electrode microstructure to full-cell electrochemical behavior. Based on optimized finite-element solvers and battery-specific algorithms, it offers high engineering efficiency and open APIs for custom algorithms and parameter calibration.

(3) BatMind Craft®: Complements physics-based simulation with AI and big data. Trained on massive online/offline datasets, it delivers high-fidelity prediction of pack behavior under complex conditions, real-time anomaly detection, early warning, and full-lifecycle data analytics across design, manufacturing, and operation stages.

Beyond technology, BDA has built a vibrant industrial ecosystem. It helps material suppliers accelerate new material discovery, enables cell manufacturers to optimize designs and improve yield, and provides BMS solutions for OEMs, creating significant value across the entire lithium-ion battery value chain and driving industry-wide R&D paradigm upgrade.

4. Summary and Outlook

This review, for the first time, systematically constructs the conceptual framework, technical system, and implementation roadmap of BDA, convincingly demonstrating its enormous potential to overcome core bottlenecks in lithium-ion battery R&D through deep integration of AI and multi-scale simulation. Although challenges remain in achieving high-precision multi-scale modeling and high-quality data fusion, BDA has laid a solid foundation for revolutionary changes in battery R&D paradigms.

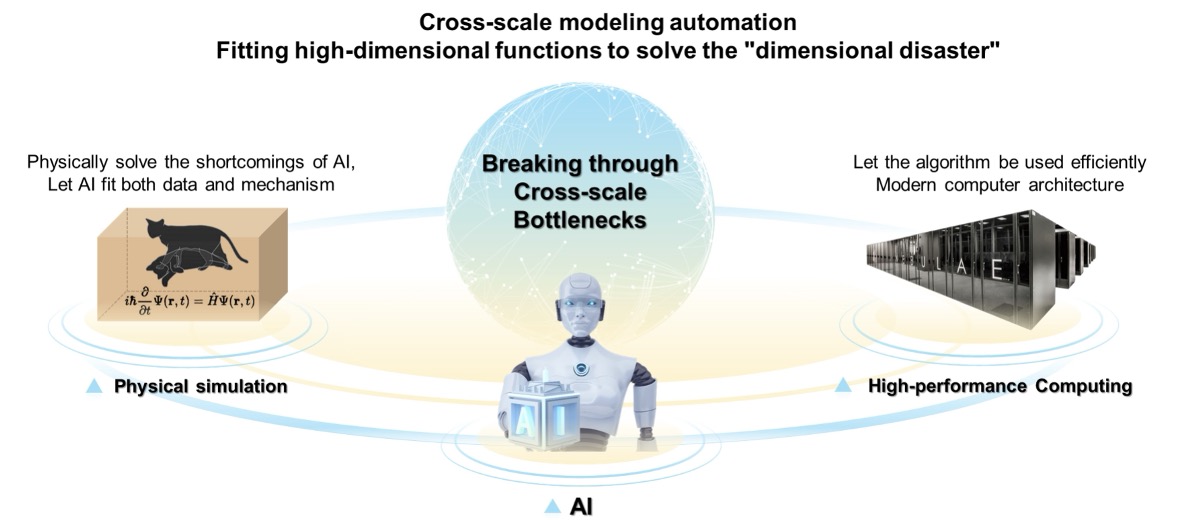

Figure 5. Schematic diagram of AI-powered, cross-scale, high-precision modeling of BDA

Looking ahead, the team suggests advancing more robust AI algorithms, multi-fidelity data fusion techniques, and reliable “design–simulation–validation” closed loops to progressively mature and industrialize BDA. For the global battery industry, BDA offers a strategic opportunity to shift from manufacturing dominance to innovation leadership, thereby consolidating and enhancing competitiveness in future energy technologies and providing a brand-new design paradigm for safer, higher-performance, and more cost-competitive next-generation lithium-ion batteries.

Corresponding authors: Associate Prof. Jiaxin Zheng (SAM), Postdoc Genming Lai (SAM), Dr. Yunxing Zuo (CTO, Shenzhen Eacomp), Dr. Jiadong Gong (Vice President, CATL Hong Kong Research Institute), Dr. Bo Xu (21C Lab, CATL), and Prof. Chuying Ouyang (Co-President of R&D, CATL). First author: Zekai Liu (2024 Master’s student, SAM). This work was supported by the National Key R&D Program of China (Major Project on New Materials) and the NSFC Key Project of Mathematical Tianyuan Fund.